缠绕机采用卧式分体结构布局,主要包括缠绕小车、绕丝嘴、伸臂、主轴、纱架、浸胶装置、预浸带缠绕装置(可选配)、电控柜等部件。配置高精度西门子840 D 数控控制系统,张力控制系统采用气动伺服控制张力器对每一团纱进行张力控制和合股纤维张力测量显示,每团纱的张力互不影响,具备停机继续保持张力的功能。该设备能够适用碳纤维、玻璃纤维及有机纤维等缠绕工艺要求。湿法缠绕能进行罐体(等开口及不等开口)、管道、球体、锥体、组合体等回转体及方形制品的纤维缠绕。

四轴缠绕机移动平台

四轴缠绕机湿法缠绕头

四轴缠绕机纱架

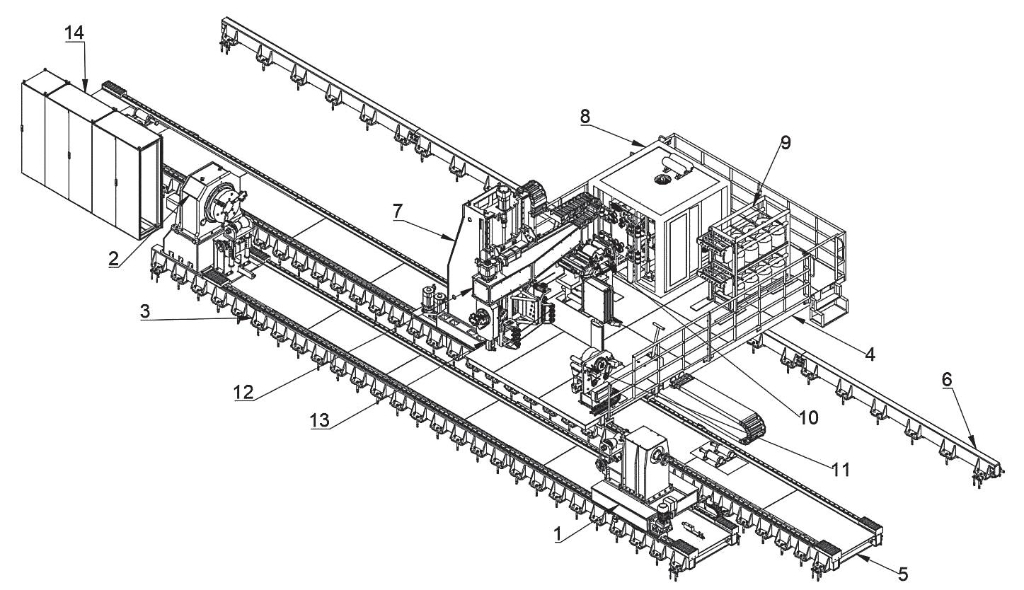

1-尾座2-主轴箱体部件3-主轴轨道基座4-平台小车5-轨道基座6-辅助轨道7-立柱部件

8-碳纤纱架部件9-玻纤纱架部件10-浸胶部件11-预浸带部件12-伸臂部件13-绕丝嘴部件14-电气柜

FCR Ⅱ 2014 卧式缠绕机主要技术参数

Horizontal winding machine parameters

1 |

最大工件夹持长度(mm) Maximum length of workpiece clamping |

16000(可定制) customizable |

2 |

最大产品缠绕长度(mm) Maximum length of product wrap |

14000(可定制) customizable |

3 |

最大缠绕产品直径(mm) Maximum diameter of wrap product |

2000(可定制) customizable |

4 |

最大夹持芯模重量(t) Maximum weight of wrap product |

15 |

5 |

最大芯模转速(rpm) Maximum speed of mandrel |

75 |

6 |

缠绕角 Winding corners |

0°~90°(根据工艺调整) adjust according to request |

7 |

小车最大行走速度(m/min) Maximum travel speed of the trolley |

60 |

8 |

小车最大行程(mm) Maximum travel of trolley |

16500 |

9 |

伸臂最大速度(m/min) Maximum speed of reach arm |

48 |

10 |

伸臂最大行程(mm) Maximum reach of arm extension |

800 |

11 |

丝嘴转动范围 Nozzle rotation range |

±180° |

12 |

丝嘴运行速度(r/min) Running speed of the nozzle |

0~30(可调) adjust according to request |

13 |

预浸带最大宽度(mm) Maximum width of prepreg tape |

150 |

14 |

预浸带最大外径(mm) Maximum outside diameter of prepreg tape |

400 |

15 |

预浸带装置扭矩(N.m) Prepreg tape unit torque |

400 |

16 |

缠绕精度(mm) Wrap accuracy |

±0.1 |

17 |

主轴定位精度 Spindle positioning accuracy |

±0.1° |

18 |

小车定位精度(mm) Trolley positioning accuracy (mm) |

≤±0.2 |

19 |

伸臂定位精度(mm) Reach arm positioning accuracy |

≤±0.2 |

20 |

纱团数量(团) Number of yarn balls (wadded) |

16(可定制) customizable |

21 |

纱团最大直径(mm) Maximum diameter of yarn ball |

220 |

22 |

纱团最大长度(mm) Maximum length of yarn ball (mm) |

280 |

23 |

单股纱团张力范围(N) Single strand yarn tension range |

5-160 |

24 |

胶槽加热范围(℃) Heating range |

室温—80 |

25 |

胶槽容量(L) Resin bath capacity |

6 |

26 |

浸胶方式 Resin method |

辊筒式上浸 Roller type upper dipping |

27 |

设备总功率(KW) Total power |

81.3 |

龙门式多工位纤维缠绕机主要技术参数

Multi-station gantry type winding machine parameters

技术参数 Technical parameters |

||

序号 |

参数名称 name |

参数指标 indicator |

工位数 Number of work stations |

3 |

|

2 |

制品最大缠绕直径(mm) Maximum winding diameter of the product |

600 |

3 |

缠绕制品最大重量(单轴)(kg) Maximum weight of wrapped product (single shaft) |

≤250 |

4 |

主轴中心距(mm) Spindle center distance |

700 |

5 |

制品最大长度(mm) Maximum length of product |

2500 |

6 |

主轴转速(rpm) Spindle speed |

0-125 |

7 |

缠绕小车速度(m/s) Winding cart speed |

0-2.5 |

8 |

小车定位精度(mm) trolley positioning accuracy |

≤0.05 |

9 |

小车重复定位精度(mm) trolley repeat positioning accuracy |

≤0.02 |

10 |

小车运动行程(mm) Trolley motion stroke |

≤3000 |

11 |

缠绕伸臂速度(mm/s) Winding overarm speed |

0-500 |

12 |

伸臂最大行程(mm) Max. reach |

600 |

13 |

伸臂定位精度(mm) Reach arm positioning accuracy |

≤0.05 |

14 |

伸臂重复定位精度(mm) Reach arm repeat positioning accuracy |

≤0.02 |

16 |

绕丝嘴翻转速度(rpm) Twist twist speed |

0-200 |

17 |

绕丝嘴翻转角度 Flip the Angle around the wire nozzle |

±180° |

18 |

缠绕角 Wrap corners |

0-90° |

19 |

缠绕角重复精度 Wrap Angle repeat accuracy |

≤0.01° |

20 |

缠绕排纱精度(mm) Winding row accuracy |

≤±0.1 |

21 |

主轴与尾座同轴度(mm) Spindle and tailstock coaxiality |

≤0.15/1000,全长≤0.5 |

22 |

丝嘴小车运动与主轴轴线平行度(mm) Degree of parallelism between the movement of the nozzle trolley and the axis of the main shaft |

≤0.1/1000,全长≤0.8 |

23 |

控制系统 Control system |

西门子840DSL Siemens 840DSL |

24 |

环向缠绕速度(m/s) Loop winding speed |

0-2.5 |

25 |

螺旋缠绕速度(m/s) Spiral winding speed |

0-2.2 |

电控张力纱架 Electronically controlled tension yarn holder |

||

1 |

容纱量(团) Yarn capacity |

24 |

2 |

单团纱重(kg) Single ball yarn weight |

≤6 |

3 |

纱团最大外径(mm) Maximum outside diameter of yarn ball |

200 |

4 |

纱团装夹内径(mm) Inside diameter of yarn ball clamp |

76±0.5 |

5 |

张力控制值(N) Tension control value |

5-160 |

浸胶系统 Dipping system |

||

1 |

浸胶槽数 Number of resin bath |

3 |

2 |

最多纱团数目(预留24团纱) Maximum number of yarns (24 bobbins reserved) |

3*8 |

3 |

胶槽导纱装置 Resin bath yarn guide device |

辊筒式上浸 Roller type upper dipping |

4 |

浸胶方式 Resin method |

上浸胶 Top dip glue |

5 |

加热功率(KW) Heating power |

2kw*3 |

6 |

浸胶槽加热温度(℃) Dip bath heating temperature |

室温—80 Room temperature |

7 |

每个浸胶槽容胶量(L) Each resin bath capacity |

5 |

8 |

胶槽控温精度(℃) Resin bath temperature control accuracy |

±2 |